Archives

THE CCM STORY - A PRESENTATION - JOHN McKENTY

Apr. 1 Seniors For Nature 1:00 p.m. Earl Bales Community Centre

Apr. 2 Milton Probus Club 10:00 a.m. Milton Sports Centre

Apr. 8 Woodstock Probus Club 10:00 a.m. Woodstock Quality Inn

Apr. 8 Pickering Historical Society 7:30 p.m. East Shore Community Centre

Apr. 9 Kingston Probus Club 10:00 a.m. Travelodge - Kingston

Apr. 16 Rideau Township Historical Society 7:30 p.m. Client Centre - North Gower

Apr. 22 Scarborough Historical Society 7:30 p.m. Bendale Library - Scarborough

May 12 Burlington Historical Society 7:00 p.m. Burlington Central Library

May 19 Brockville Probus Club 10:00 a.m. Brockville Country Club

May 13 Streetsville Probus Club 9:30 a.m. Mississauga (Vic Johnson Ctr.)

May 14 Georgetown Historical Society 7:30 p.m. Knox Presbyterian Church

May 21 Abbotsford Heritage Association 1:00 p.m. Glebe - Ottawa

If you're in the neighbourhood, drop by and say hello.

Better yet bring along your vintage CCM for folks to see.

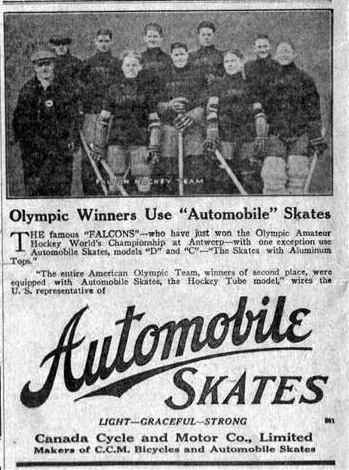

CANADA"S FIRST OLYMPIC GOLD MEDAL HOCKEY TEAM - 1920

Winnipeg Falcons

Thanks to Larry Tait.....

to

FRANCOIS MORIN

the 500th member of our Forum

LAST CALL

2014 Vintage CCM Calendar

Didn't find one under the tree.

Order now! Only a few left.